Metal manufacturers and suppliers often offer a combination of metal cutting and bending

services for the best results. When we talk about plasma cutting, let us understand what we

mean. The plasma cutter is the most popular tool in this industry for metal fabrication work

as it gives fine-tuned and precise results, which is very useful in the manufacturing of

customized metal products. The action of cutting is performed with the help of a plasma

torch. Gas is sent at a very high speed. The gas passes through a nozzle and, with the help of

an electrical arc, the metal melts. Compressed air is used to blow away the metal that is

melted.

1. Easy to use: Tool which comes with simple instructions and gives best results is always

welcome. The portability of plasma cutter makes it all time favourite with the metal

manufacturers. They can carry it wherever they want as per the demand of the work

and the project. So, if onsite cutting is required, it can also be done with ease.

2.. Precision cutting: The biggest advantage of plasma cutting technology is it has

precision cutting. This is also true that it requires the touch of an experienced hands

to get perfect cut but with plasma cutter, it is a cake walk to get angles, designs cut on

a metal sheet with exact precision.

3. Versatility: One cannot measure the versatility of the plasma cutter, with it, we can

cut different types of metal without much problem. With the help of electric arc, it

can cut any type of metal whether iron, aluminum, steel or copper or any other. It is

also considered to be cost-effective as well as energy-efficient option for cutting. In

fact, it can cut metal stacked on top of one another.

4. Fast Piercing: The speed at which plasma cutter can pierce and cut, is much better

than other cutting methodologies. There is no heating time required for preparing the

tool for cutting, so it makes it really faster and easier at the same time.

5. Low-cost maintenance: Wear and tear in the plasma cutter is much lower than other

tools. This brings down the cost considerably and also gives good results. It rarely

requires change or replacement and can work for years. This makes it value for money

with good return on investments both for the metal fabricators and the customers.

Besides, these five benefits of plasma cutting are also good for cutting metals fast as it brings

the time by one-fourth in compared to other techniques and helps in timely completion of

projects. This even brings down the cost of the total project as time is reduced with better

work quality.

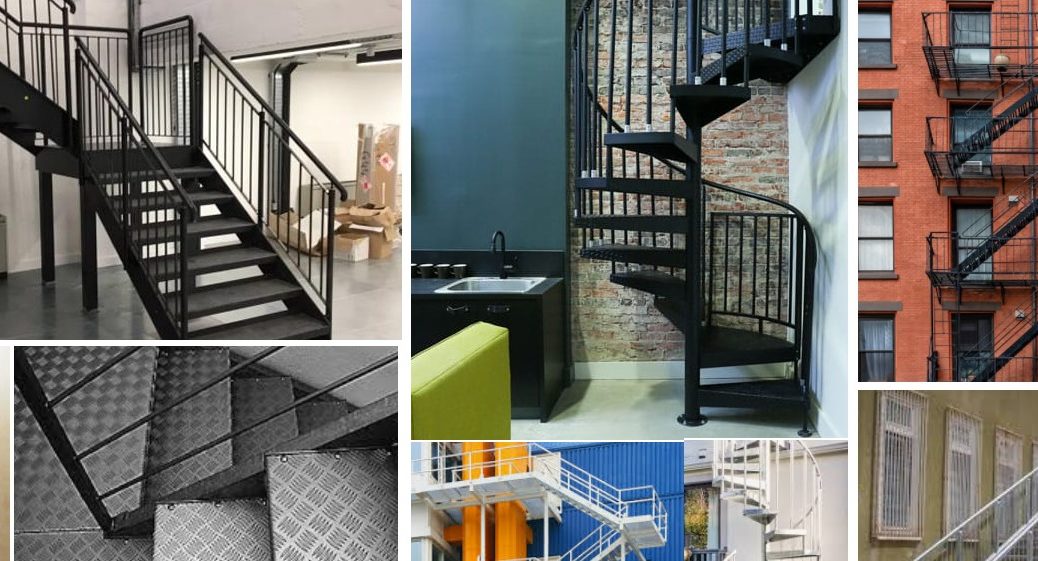

Omni Steel Supply are professional metal fabricators and welders and offers services both for

commercial and residential purposes. They have different metal cutting and bending

technologies but they also consider plasma cutting, the best way to get the most effective

metal cutting results. If you are looking for a plasma cutter and would want more details, get

in touch with us today.