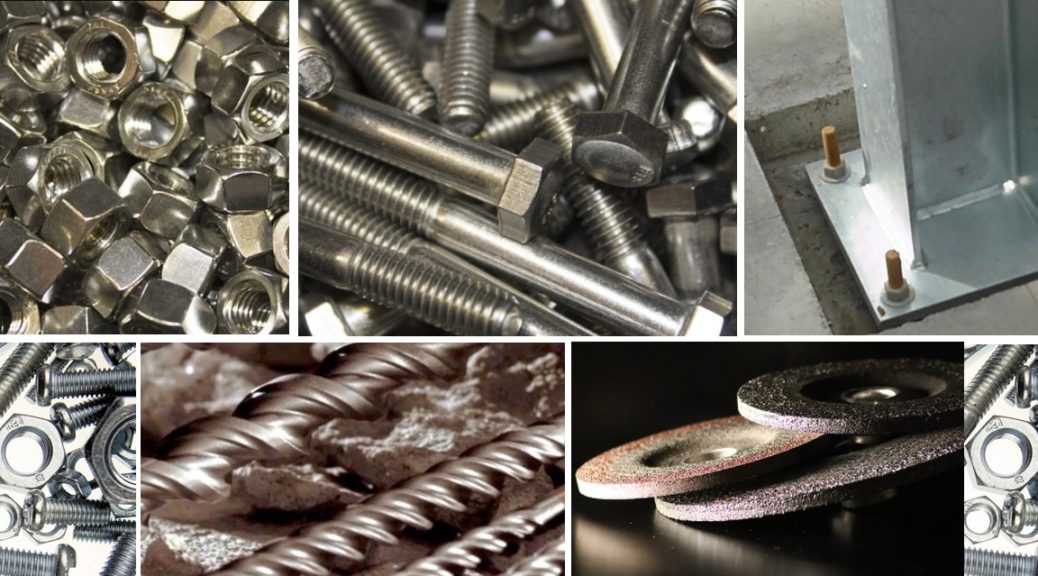

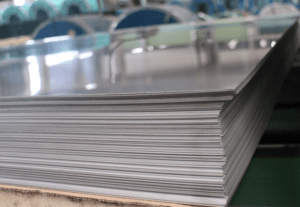

While discussing steel and its properties with high school students, a simple truth held the ground and proved steel is omnipresent. Sitting in the comfort of your home, take a look around, you would be amazed to realize how steel has become a part of us and it is available in everything that we touch either directly or indirectly. The sustainable and eco-friendly material is the most revered one and changing the dynamics of industry.

The world of cellular device

Communication has undergone a revolution, today time-zone is non-existential. Even after living in different zones, we are connected in real time both with business and family. All this revolutionary fete is the work of steel, which is the backbone of cellular industry. Steel and its alloy have leveraged us in many ways, and expanded the scope of work without contributing to increase in carbon footprint.

Mushrooming of OTT Channels

Watching our favorite movie or web series over OTT, we forget to acknowledge the fact, the device via which we are enjoying is the outcome of steel available to us. It certainly feels dominating at times, living in the world of metals but they are transforming our life in many ways and making it beautiful to live. With each day, there is a new addition from the world of steel.

Photography

One in every ten, has photography as their hobby and passion. They either prefer using a camera or phone to capture precious moments of life and picturesque nature. It is not only your device but props could also be an outcome of steel or other metals. Fashion photography or trick photography involves a lot of lighting arrangements and other props made of steel to reflect light for a better frame.

World of Music

Well, we do not want to interfere the organic and pristine world of composition…but it is also not an untouched industry. From instruments to recording to editing, everywhere steel is found. Equipment used will either have steel or some other metal in the making or a couple of parts made out of metal. Creativity gets life with a little of steel in it, they do not make it cold rather infuses life and breath.

Knowing or unknowingly, metal moves along with us. They are making life possible to enjoy and see it in myriad of hues. Imagine going on vacation and here also you would be surprised to witness a string of things made out of steel or metals. Silently and artistically, it is making the world a better place…a little of steel is in everything like Midas Touch!

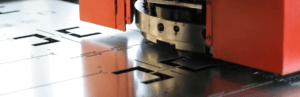

Omni Steel Supply is a professional metal manufacturer and supplier in and around New York. They take both online and offline orders. If you want to know how steel and metals are becoming a big influencer and turning the tables, just fill the form below and get the chance to know enter the world of steel. It is amazing and full of surprises, plus a good return on investment.