New York is a bustling metropolis with a diverse range of industries and a high demand for metal fabrication services. From construction and manufacturing to transportation and logistics, the state of New York relies on the strength and durability of steel and aluminum to keep its infrastructure running smoothly.

One of the most popular materials for metal fabrication in New York is aluminum diamond plates. These plates are made from a durable and lightweight aluminum alloy that is resistant to corrosion and wear. They are often used in construction, transportation, and manufacturing applications due to their strength and durability. In New York, aluminum diamond plates are commonly used for flooring, stair treads, and loading docks.

Another popular material for metal fabrication in New York is steel. Steel is a strong and durable metal that is often used in construction, transportation, and manufacturing applications. Steel angles, for example, are a common structural shape that is used in construction, transportation, and manufacturing applications. They are often used to reinforce structures and provide support. In New York, steel angles are commonly used in the construction of bridges, buildings, and other structures.

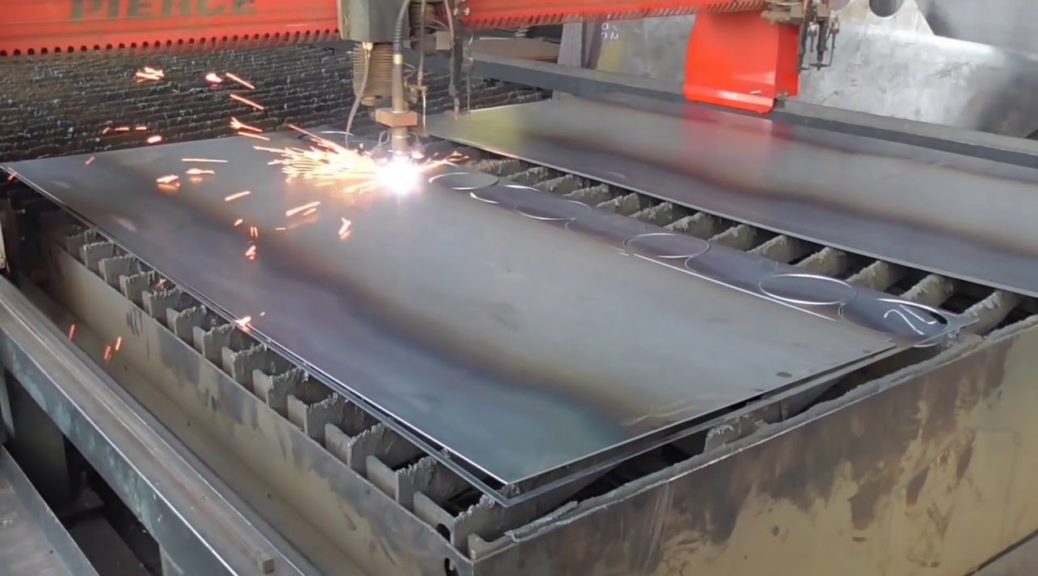

Steel drilling is another important aspect of metal fabrication in New York. Steel drilling is the process of making holes in steel using a drill press or CNC machine. This process is essential for many constructions, transportation, and manufacturing applications. In New York, steel drilling is commonly used in the construction of buildings, bridges, and other structures.

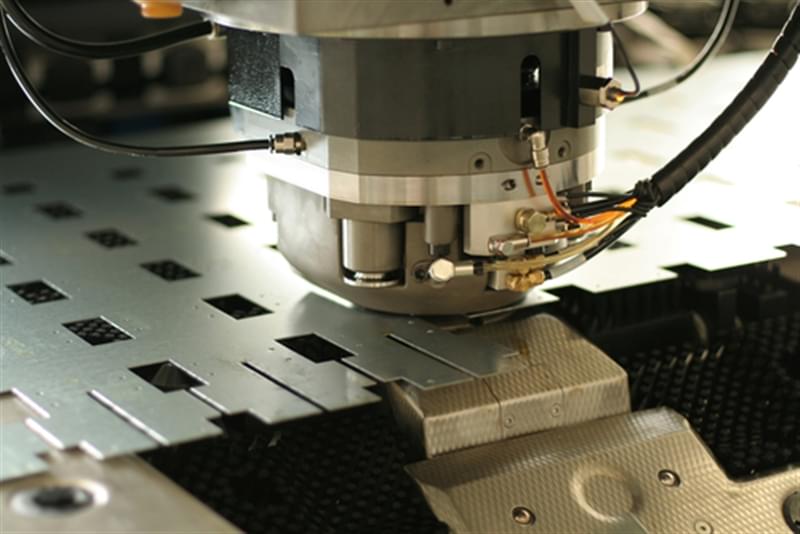

Custom metal fabrication is also a popular service in New York. This process involves creating custom-made metal products to meet the specific needs of a customer. These products can be made from a variety of materials, including steel, aluminum, and other metals. In New York, custom metal fabrication is commonly used in the construction, transportation, and manufacturing industries.

Overall, aluminum diamond plates and steel fabrication are essential for the success of many industries in New York. From construction and transportation to manufacturing and logistics, the strength and durability of these materials are crucial for the state’s infrastructure. With steel drilling, custom metal fabrication, and a wide range of steel shapes and aluminum alloys, New York’s metal fabrication industry is well-equipped to meet the demands of its diverse range of industries.