Interesting as it may sound, steel punching is one of the solid techniques used for shaping metals either for commercial or residential purposes. Best angle of this technique is, it can be a great contributor in creating multiple types of shapes out of metal sheets of different thickness. Additionally, it increases the aesthetic appeal of the metal sheet by varying punching styles and ideas.

Let us see how steel punching processes work and are instrumental in giving meaning to metal sheets used in construction work. Whether we consider punching for industrial or residential purposes, the process is almost the same. But, for delving deeper into the technique, you can always consult your domestic metal contractor, here, we share the process in the simplest way possible.

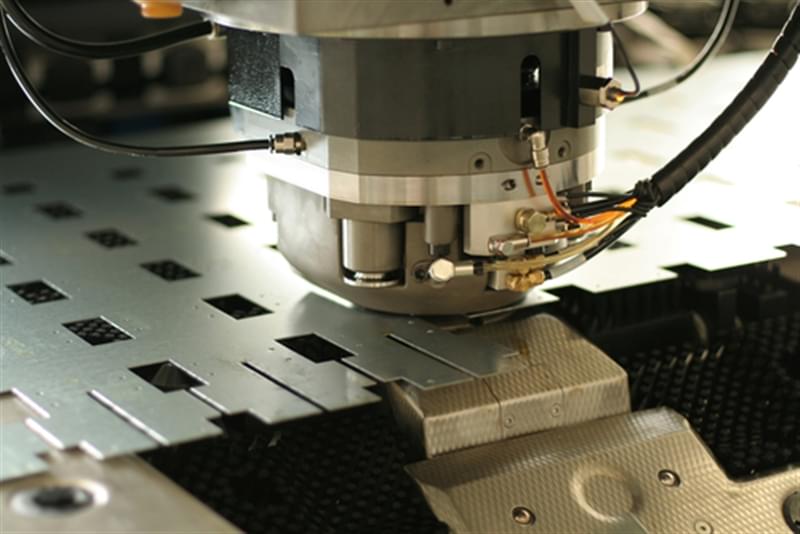

Steel punching, irrespective of the thickness, is carried out via compression force. The main purpose of the force is to give pressure on the steel sheet, this helps in creating holes and required indents for giving a distinct feature to the steel sheet. The technique is precise, very quick and is pretty effective in getting the desired results. It is much effective in obtaining ornamental designs for sheets and for reinforcing purposes wherever required. For industrial sectors, it has proved to be very helpful in forming different shapes from various parts of the metal.

For punching, the sheet is pressed between the dye and heavy machinery that puts pressure on the sheet. It gets fractured and a hole is cut in the sheet, once it is done, punch is removed and the sheet comes out. Manufacturers have knowledge about the punching machinery and the pressure that has to be initiated on the metal sheet, accordingly they exert the pressure to get the desired shape through the punching process.

Why is the punching quality affected?

A professional steel punching contractor, would point to following things when it comes down to punching quality.

- The first one is shape or size of the punching press and the dye

- Second factor is the force exerted on the sheet, it has to be done by a qualified and experienced hand else a bigger and wider dent could be done and ruin the whole steel sheet.

- Density of the metal sheet is also a very important factor to consider while applying the punching force

A trained professional always guides and gives the correct suggestions when it comes down to steel punching. Shaping of Metal sheets is done by a different process and it is called stamping of metal sheets.

There may be numerous questions which must be troubling you and putting you in doubt. Yes, it is surely tough to decide whether it is the best thing to do for customisation of your steel sheet.

If you are in doubt or are unsure about your decisions about steel fabrication, contact us today.

We at Omni Steel Supply can connect you with the experts who specialize in steel punching and give you adequate information to bring clarity in your choice. Contact Omni steel supply for steel services and supplies in Jamaica, Queens and Newyork area.