Set up in the year 2014, Steel Safety Day is celebrated on 28 April every year since then. The day

coincides with the International Labor Organization’s World Day for Safety and Health at Work. It was

essentially recognized to spread awareness for five main reasons of incidents and to ensure there is

enough safety norms followed across the steel industry world over.

The five major concerns of safety incidents are—

1. Machinery Safety, 2. Working at heights, 3. Falling Objects, 4. On-Site Traffic and 5. Process Safety Incidents

To commemorate the day, each year a theme is decided based on the five causes of safety incidents.

It can either be one of the cause or something related, this is done to bring the focus on serious safety

concerns related to the steel and metal industry. This year the theme is working at heights, the idea

behind selecting any of the issue is to highlight the rising threats and how these should be addressed.

It is certainly a rising issue among the manufacturers as they are often worried about health of their

engineers and staffs working onsite.

Omni Steel Supply, which is one of the leading manufacturer and distributor of high quality, strong

and attractive steel and stainless steel, take deep interest in the safety of its work-force. They have a

very detailed safety protocol for those working at heights. In fact, they are very particular about both

their workers and people passing through the construction sites. They believe in safeguarding lives is

the most important work of humanity and thus ensure, pedestrians are well informed and proper

precaution structure is in place.

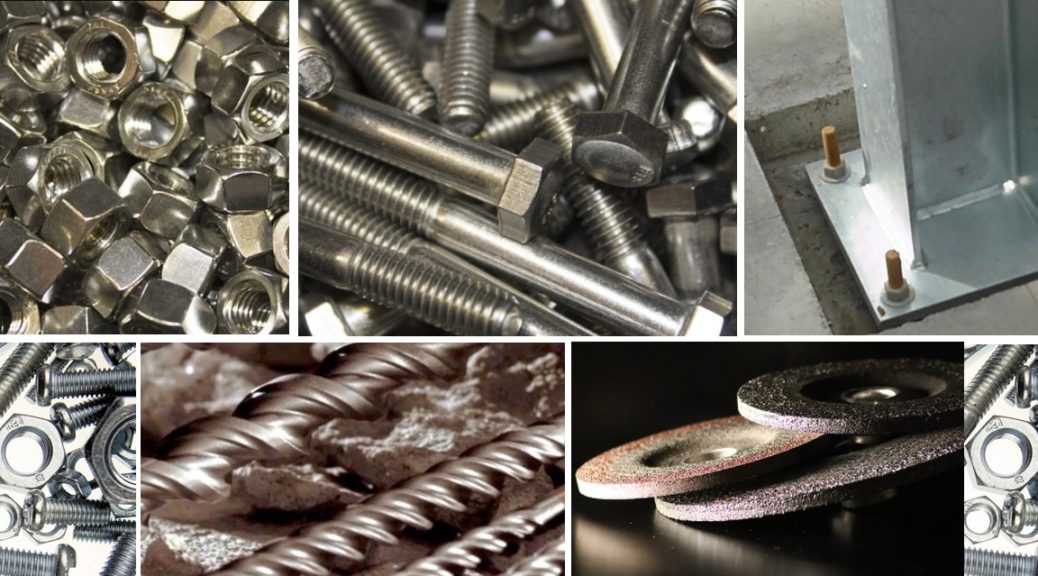

Structural or fabricated metal and steel works are in great demand. The work of the fabricated steel

designs is done in the warehouse, but installation is at on-site. These require handling of nuts and

bolts to secure the frame that is going to be installed. Since, the company had been in the industry for

quite some time, they take enough precautionary measures needed for the management of tools from

falling down or hurting the workers or the people passing-by.

Now, when we talk about working on heights, the theme of the world steel day, Omni Steel believes

in taking following measures—

• They provide their staff with proper uniform, which can protect them from getting hurt

• Necessary rescue guidelines, like providing net to secure the health of the workers

• Helmets, gloves, boots, glasses for eyes

• They also check for any health issues when an employee has to ascend height for

accomplishing a task.

• They provide state-of-the-art equipment with modern safety trainings.

• Special measures are taken when workers are working in the harshest weather condition

Omni Steel Supply has been the most trusted in US for the work they have done and the way they deal

with their employees. Along with achieving deadlines, meeting customer satisfaction, providing best

designs, and smooth delivery and customer service, they also guarantee safety of their workers

whether working at heights or working in difficult conditions or any other challenges of work. They

are here because they care!