Metal bending is a fundamental process in the field of metalworking, essential for creating a wide range of products, from simple brackets to intricate artistic sculptures. Understanding the various types of metal bending, the metals that can be bent, the tools involved, and the benefits of this technique can provide valuable insights into the world of metal fabrication.

-

What is Metal Bending?

Metal bending is the process of reshaping metal sheets or bars into specific angles, curves, or shapes. It involves applying force to the material, causing it to deform without causing cracks or fractures. The ability to bend metal is crucial in manufacturing industries, construction, automotive, and even in artistic endeavors.

-

Bendable/Formable Metals

Not all metals are equally bendable. Some metals possess the necessary properties to be easily formed, while others are more challenging to work with. The most commonly bendable metals include:

– Aluminum: Aluminum is known for its excellent formability, making it a popular choice for bending in various industries, from automotive to aerospace.

– Copper: Copper is malleable and often used in electrical applications, where bending into precise shapes is crucial.

– Brass: Brass combines the malleability of copper with the corrosion resistance of zinc, making it suitable for decorative and functional purposes.

– Mild Steel: Mild steel can be bent with relative ease and is commonly used in construction and metal fabrication.

– Stainless Steel: While less malleable than mild steel, stainless steel can still be bent using specialized techniques and equipment.

-

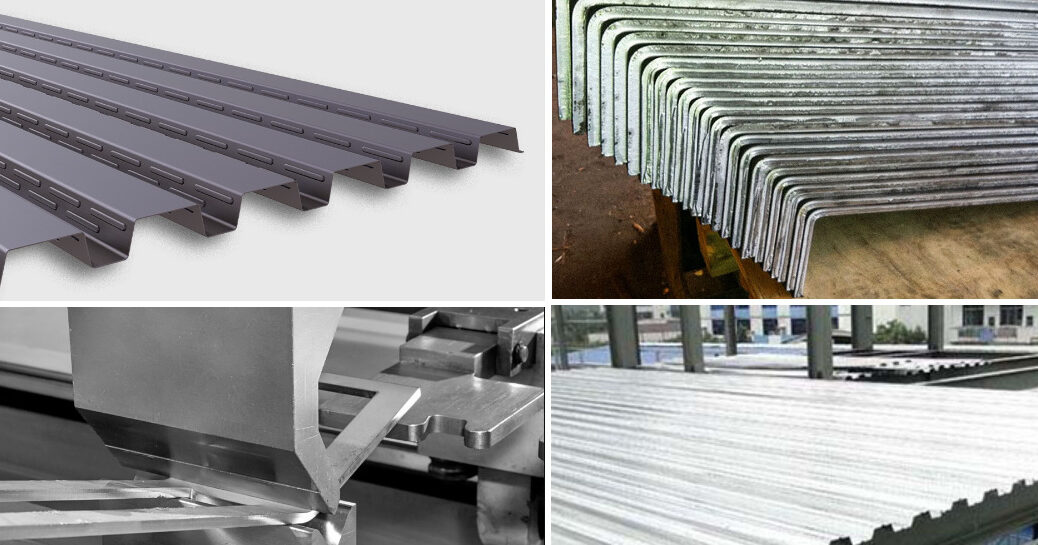

Different Types of Metal Bending

Several techniques are used for metal bending, each suited to specific applications:

– V-Bending: In this method, a V-shaped die and a punch are used to bend metal sheets. It is a highly precise technique often used for manufacturing brackets, enclosures, and other similar components.

– Press Brake Bending: Press brakes are versatile machines that can perform various bending operations, including air bending, coining, and bottoming. They are commonly used in the production of machine parts and architectural components.

– Roll Bending: Roll bending involves passing a metal sheet or bar between three rollers that apply pressure to create curves or cylinders. It is frequently used in the construction of tubes, pipes, and rounded profiles.

– Tube Bending: As the name suggests, this method is specifically designed for bending tubes and pipes, commonly used in industries like plumbing, HVAC, and automotive.

-

Tools for Bending

The tools used for metal bending depend on the specific technique employed. Common tools include press brakes, rollers, tube bending machines, and hydraulic or mechanical benders. The choice of tool depends on the material, the desired bend radius, and the precision required.

- Benefits of Metal Bending

Metal bending offers numerous advantages:

– Design Flexibility: Metal bending allows for the creation of complex shapes and designs that would be difficult or impossible to achieve through other methods.

– Strength and Durability: Bending does not weaken the material as cutting might, making it suitable for applications that require strength and durability.

– Cost Efficiency: Bending can often reduce the need for welding or other joining methods, which can be time-consuming and costly.

- Tips for Forming Metal

Achieving high-quality metal bends requires skill and knowledge. Here are some essential tips for successful metal forming:

– Ensure the material is at the appropriate temperature, as metals can become brittle when cold.

– Use lubricants to reduce friction and prevent scratching or marring of the metal surface.

– Properly secure the workpiece to prevent it from slipping or moving during the bending process.

– Follow safety procedures and use appropriate personal protective equipment when working with metal.

In conclusion, understanding the different types of metal bending, the metals that can be bent, the tools involved, and the benefits of this process are crucial for anyone involved in metal fabrication. Metal bending is a versatile and essential technique, with applications ranging from manufacturing to artistic expression, making it a valuable skill in various industries.