Spot welding, also known as resistance welding, is a process of joining two or more metal sheets by passing a high electric current through them at a specific point of contact. The heat generated from this current melt the metal at the point of contact, which fuses the two metal sheets together. This process is widely used in the automotive, aerospace, and manufacturing industries for its efficiency, speed, and reliability.

Types of Resistance Welding

Resistance welding encompasses several types of welding techniques, such as spot welding, seam welding, projection welding, and flash welding. Each technique has its unique advantages and applications, but spot welding is the most common technique used in industrial applications.

Seam welding, also known as continuous welding, is used for welding long sheets or plates continuously. Projection welding is used for welding sheet metal parts that have raised or embossed features. Flash welding is used for welding large and complex structures such as aerospace components.

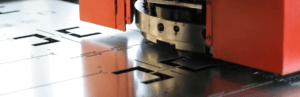

How Does Spot Welding Work?

Spot welding is a simple process that requires a power source, electrodes, and a workpiece. The electrodes clamp the metal sheets together and apply pressure to create a good contact between them. When the electric current passes through the electrodes, it generates heat at the point of contact, which melts the metal and fuses the sheets together. The amount of heat generated depends on the electrical resistance of the metal sheets, the size of the electrodes, and the amount of pressure applied.

Advantages of Spot Welding

Spot welding has several advantages over other welding techniques, such as:

Speed and Efficiency: Spot welding is a fast process that can join two metal sheets in a matter of seconds. It is an efficient process that can join multiple sheets simultaneously.

Cost-effective: Spot welding requires minimal equipment and can be done on a small scale, making it a cost-effective option for small businesses.

High Quality: Spot welding produces a strong and consistent weld, which is essential for applications that require high precision and accuracy.

Environmentally friendly: Spot welding produces minimal waste, making it an environmentally friendly option compared to other welding techniques.

Limitations of Resistance Spot Welding

While spot welding has several advantages, it also has some limitations, such as:

Limited Thickness: Spot welding is limited to metal sheets with a thickness of up to 3 mm. For thicker sheets, other welding techniques such as arc welding may be required.

Material Compatibility: Spot welding works best with materials that have similar electrical conductivity. Dissimilar materials may require additional preparation or a different welding technique.

Surface Preparation: Spot welding requires clean and flat surfaces for optimal performance. Any contamination or uneven surfaces can affect the quality of the weld.

In conclusion, spot welding is a widely used and efficient welding technique that is essential in the manufacturing industry. It offers several advantages, such as speed, efficiency, cost-effectiveness, high-quality results, and environmental friendliness. However, it also has some limitations that should be considered before using it for specific applications.

We provide Custom welding solutions for Domestic and commercial needs. Contact us today!

structural steel welding, Domestic welding services