With changing phases of evolution, lifestyle gets new meaning and purpose. Today, with digital revolution, our life is wired but something which is still constant and we all love is sitting in outside and enjoying the altering colors of sky as the day progresses. There’s a range of furniture available in the market for your garden, patio and for your balcony from metal to wood to cane to more. Over here, let us scroll through tips on how to maintain metal furniture and make it look new for years.

Some really simple and must to steps in maintaining metal furniture or any other kind, so that they can look as new for ages are—

- Make it a habit to clean your stainless steel, aluminum or brass furniture on a regular basis. Do not let dust or water drops stay on them for long, you can use any soft cloth to the work.

- It would be a good idea to wash the furniture with soap and water, preferably with one that does not contain any pH-negative powder.

- It is very important to wipe or wash in the direction of the lines, this does not bring circular lines on the polish and keeps it in good condition for long. Do not wipe with the cloth dripping with water, this can leave mark on the furniture.

- Instead of scrubbing with harsh scrubber, try removing stains with soft cloth, it helps.

- Annual polishing or painting of metal furniture does a lot of good and increases the life of the furniture. Maintenance of painted furniture is also easy, scratch etc can be easily taken care by painting it whenever required.

- If the weather condition is harsh or extreme, then to avoid rusting from humidity, it is necessary to clean on a daily basis with a soft dry cloth and paint as and when possible on regular intervals to ensure good life of your outdoor furniture.

- If you have powder coated aluminum furniture, then you can dry wipe it for securing the look and finish. And, also to increase the life of furniture.

- Stainless Steel furniture is super easy to maintain, wash it regularly with detergent and water. The main idea is to keep it free from dust and keep it dry. This will avoid corrosion and stay the same for years.

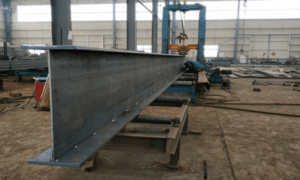

Metal furniture has a very suave and elegant styling, especially those which are for outdoor use. Metal is not only strong and has long life, it is regarded as an eco-friendly material that can be reused without losing its inherent quality.

Omni Steel Supply is a NY based metal manufacturer and supplier who have experience in manufacturing metal furniture of various styles. They can also guide you about stairs built inside and outside homes. If you are in search of metal furniture for your patio or garden, then get in touch with them today by filling the form below. They would be glad to guide you through and bring on table options for fabricated metal products.