Steel has a huge market share and is continuing to grow steadfastly. Across the globe, it is

increasingly being used by the construction industry, whether it is for building the frame or

for interiors or for roofing or for lawn upkeep. You would notice how it has captured the

market and adding aesthetic value as well.

Without doubt, it is pretty evident steel has good market because it is strong, durable,

resistant to natural disasters as hurricanes, tornadoes etc. and is sustainable. Yes, steel retains

its features even after undergoing several recycling processes. Also, one of the hidden or we

can term implicit advantages of using steel is during natural disasters, a building could bargain

better deals from insurance companies as steel is a durable material.

At Omni Steel Supply, we are listing some of the immediate advantages of steel in the

construction, which is helping in its popularity.

• Sustainability: Steel is a reusable material and it holds on to its qualities even after

several uses and recycle. This makes it the most desired substance in the present global

warming crisis.

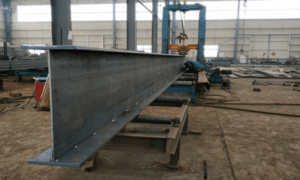

• Speeds up the construction: Steel framework is manufactured in the warehouse, in

other words it is prefabricated and only assembling and installation work is done at

the site. It speeds up construction work and does away with any clutter on work sites.

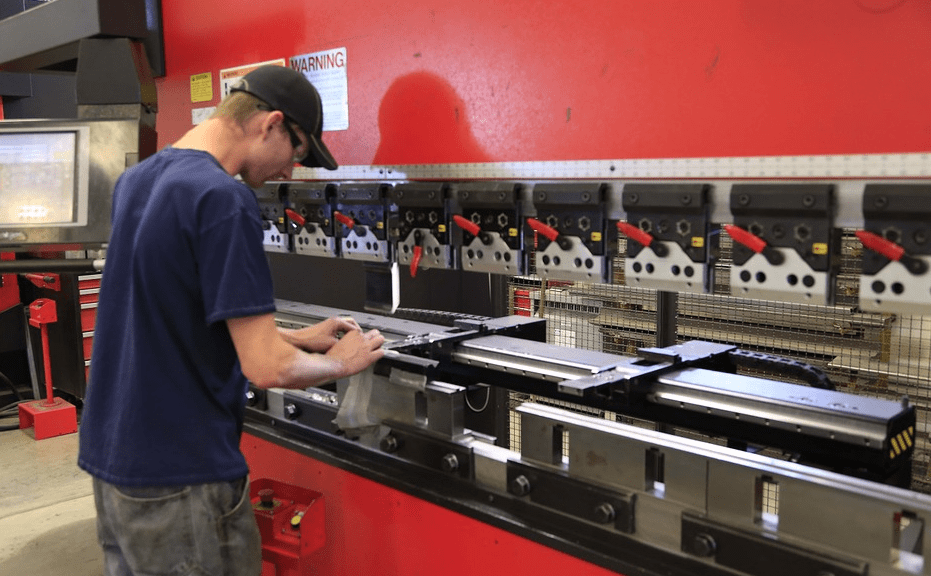

• Innovation: It is simpler to create innovative designs with steel or any metal. All

designing work with the help of high-end software, which makes working really

smooth. Each dimension, angles, 3D panning of the design, are worked out before the

final work commences. This gives scope to change and adapt as one realizes various

difficulties.

• Safety: Prefabricated steel works and pre-decided lifting areas make it easy and at the

same time bring safety for the workers. The industry is known for taking good safety

measures, which makes working really fast.

• Worth every penny: Steel is regarded as value for money material as without loss of

material, it can be used many times

• Robust and ductile: Since, it has great resistance power, it responds to carrying of load

with ease and do not crumble under pressure.

• Architectural flexibility: Steel is versatile material, and this very feature gives

architects pleasure of realizing their ideas without much ado. Even steel sculptures

can be created with the help of steel and its alloy.

• Onsite configuration gives ease in adaptability: Since steel is assembled on the site, so

it is easy to adapt to any required changes regarding the assembling.

• Weight: It is a light weight material, so delivery and installation is not much of a

botheration. In fact, it is a common thing that more floors are added when there is a

requirement.

Omni Steel Supply, is a professional manufacturer and dealer of steel and other metals

required for construction industry. If you want good quality steel for your next project and

looking for understanding of its alloys or configurations, then fill the form below and we

would get in touch with you. We will deal with remote orders.