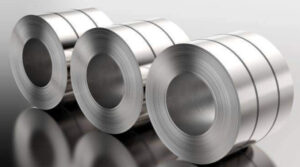

Steel Coils considered to be versatile and strong metal are used for building walls, ships, roof panels and several other construction and engineering works. It is essentially finished steel sheet that has been coiled or wound several types along the width of the metal sheet that adds to its features. It is a known truth steel coils with coatings become moisture and weather resistant and is one of the most eco-friendly materials for construction purposes. Steel coils are available in different grades and each has its own importance in the world of metal manufacturing works. Over here, we would not get i12a discussion on steel coil grades but try to touch uses of steel coils, as steel slabs when rolled into coils get ductile, has high strength, is of high grade and ductile. Coiling of steel makes it a friendly option for those who want to customize the metal for their specific needs.

- Automotive Industry: Steel in general has an innumerable usage in the automotive industry, from body parts to machinery, all require steel in different ways. So, you may find it in chassis, wheels, suspension, car doors anywhere that you can think. It is an ideal choice for vehicle’s combustion engine as it is non-combustible, has high resistance to heat, durable and top it has high strength-to-weight ratio. The best feature of steel coil is it can be recycled and reused without the fear of losing its basic quality, it can be coiled again and again for making new products out of it for automotive parts.

- Electronic parts: Steel coils as mentioned earlier has high melting points which makes it a suitable material for cases of mobile phones, circuit boards, CPUs others. It is the most favorite part in the manufacturing of electronic equipment and parts as the melting point is very high owing to which electronic gadgets have better life span, require negligible maintenance and are not very expensive.

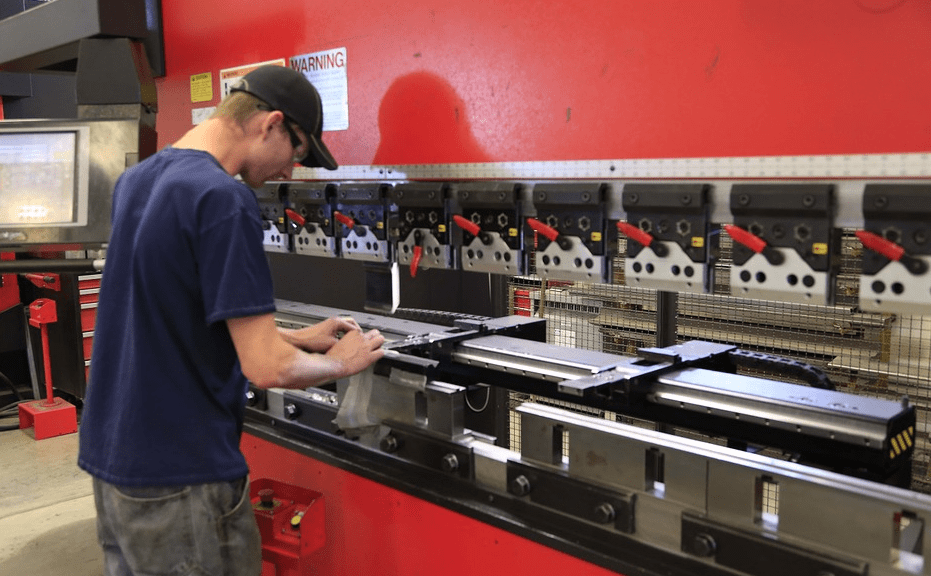

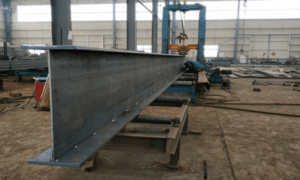

- Structural Steel: With steel coils, fabrication works get really simple and easy, we can get any structural designs which is strong and can withstand force. Coils can be wound into I-beams, angle bars, H-beams or others as per demand and need for structural purposes. Demand for structural steel is comparatively higher than any other manufacturing materials as it is not too much a task to customize steel coils to any shape, size and design. They are known to be used for providing framework support for enclosures or walls, structural steel can be seen in almost all the buildings. The beams rolled out from the coils are used in the ceilings that provide enough strength to control winds and keep the structure solid and safe.

-

steel coil

Omni Steel Supply is a renowned professional manufacturer and supplier of steel and metals. They even deal in steel coils and have been fabricating the coils for carving out various interesting designs for commercial and residential uses. If you wish to know more about metal and steel coils, do not forget to reach to us by filling the form given below.