Ornamental Iron & Steel design and accessories bring volume and add elegance even to a

mundane corner or space. Interestingly, all designs can be customized, can be carved out of

any kind of metal and can fit in all types of architectural structure and designs. From our

experience at Omni Steel Supply, we can assure ornamental steel works do require

expertise and understanding but can be created without any trouble. To find a reliable,

experienced and knowledgeable steel fabricator in NY city, Jamaica or elsewhere, we have

brought a list of five questions, which can accelerate your selection process.

5 Questions for finding the right steel contractor

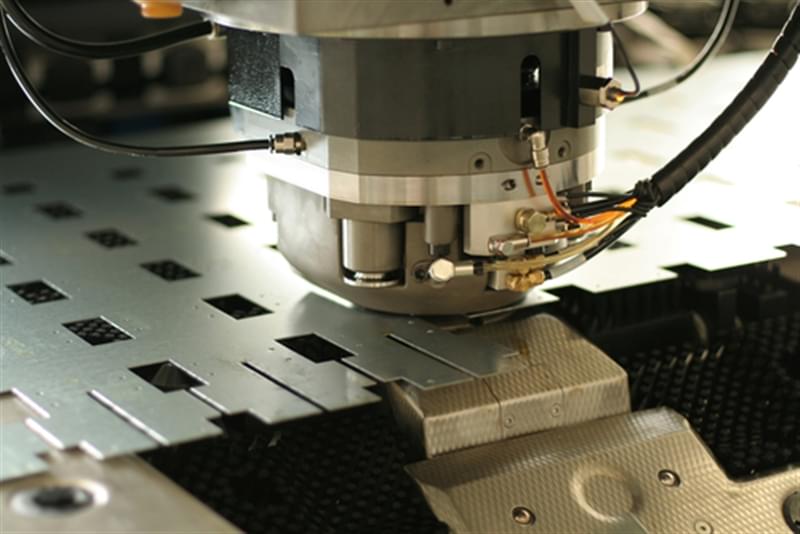

1. How do you handle complicated designs: Designs can be as simple as it can be and

as difficult as the imagination. A fabricator will never be hesitant in making your ideas

a reality. A professional contractor has high end software to get the exact dimensions

and curves for ornamental metal accessories before putting the metal under an

intriguing welding and moulding process.

2. How can you guarantee the fabrication process: The moment designing work sees

the light of the day, we move to the next step which is fabrication. It is one strenuous

process as it involves a lot of small and big steps like skill to understand the design,

how much heat is required for welding, cutting and moulding work especially if the

design at hand is little intricate and detailed. Only experienced hands with an artistic

bent of mind can move ahead with it.

3. How smooth is the installation work: As the fabrication nears end, we discuss the

installation work of the ornamental accessories. It has to be really smooth to relax the

nerves of your client and for building a long relationship. Depending on the nature of

work whether it is small or big or if it is complex or simple, an estimate of installation

time is given to the customer, within which work is completed. Delivery is done by the

fabricator at the desired location with complete installation.

4. How do they guarantee the work: Once installation is over, finishing touch is provided

to the client for accessories installed. It is essentially for increasing the life of the part

and for enhancing the beauty of the metal. Finish for the metal product can be

anything from metallic to black to matte and more.

5. How reliable is the customer care: Mostly, it has been noticed, once the installation

and delivery of the product is complete, the fabricator snaps all the relationships with

the client. To resolve issues after installation, you need to connect with a metal

fabricator with a trustworthy customer care department.

Omni Steel Supply, has a varied range of metal accessories and we also customize as per

our clients’ requirement. We even take orders remotely and can work on any kind of designs.

Our experienced designers and engineers can deliver the idea that is exactly in sync with the

one floating in your mind. Get in touch with us today for queries and timely project

completion.