Among many small and important facts about structural steel, one interesting truth is, steel

is a part of almost each type of industry. You name it, and you would notice a prominent use

of the metal in that field. From commercial to residential to manufacturing, all depend on

steel for their work. We are already aware of the varied use of structural steel for commercial

purposes but do we know it is being widely used for residential construction.

As a seasoned professional steel fabricator would like to put it, with high-end technological

tools, it is becoming quite convenient to customize a metal sheet as per design and

requirement of a client. When you are dealing with a professional steel fabricator, you would

notice how they streamline a project into phases and explain complexities involved in the

completion of a project.

Some of the benefits of working with Professional Steel Fabricators:

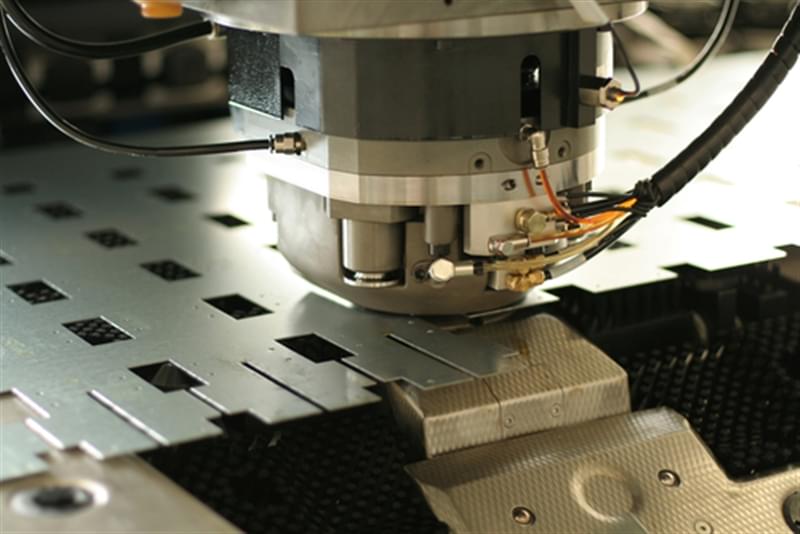

• Precise cutting of steel, aluminum: With advanced and right kind of tools at their

disposal, professional metal fabricators, works with precision. They work in sync with

the designers and the clients’ ideas about the end product.

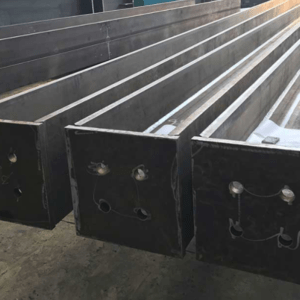

• Welding tools: Each sheet is of different density and require heat at various

temperature. Not all need to be exposed to high level of heat and temperature as it

can destroy the whole concept of welding. Only a trained welder can evaluate this and

control the level of heat along with the appropriate tool needed.

• Protection against corrosion: The real concern found in owners of property is resistant

power of metals as steel and aluminum to rust. A good steel manufacturer can easily

calm your concerns related with rusting and corrosion. They know exactly how to

increase the life of any metal and which alloy can withstand the climatic condition of

NY, Jamaica, Queens and other neighboring areas. They give complete insight on the

metal and also suggest which would be the best choice for a particular project.

• Design details: In present times, customized steel or other metals is used for

constructing circular staircase, for ramps, for shelves, for car interiors and several

more purposes. Steel manufacturers are equipped with sophisticated software, which

can give shape to any idea before it goes for final cut. Detailing is done as far as it is

possible and this gives a meaning to any project. Professionals ensure that customers

are satisfied and get what they have desired.

• Reuse of metal: With chiselled steel fabricator, you can enjoy versatility of work

quality. They not only deliver what is required of them but also give suggestions on

how to reuse a particular metal sheet or scraps dumped in garage or in your store.

Omni Steel Supply is a professional steel fabricator and welder, with our years of experience,

we not only deliver work on time and with exact details, we also connect you with the best

engineers to guide and help. If you are looking for advice on steel products, then get in touch with us Today!