Freedom unleashes new meaning to mankind; automation of industry is one such proof. It has transformed the whole working environment and has increased the scope of work. Metal fabricators have also got a taste of robotics technology and working with AI. With demand for labor increasing in metal manufacturing industry, and the industry witnessing a dearth of good workers, metal manufacturers are exploring new ways to deliver quality and efficient work to their customers. With the help of technology, they have managed to work in close proximity with the industry and deliver extremely high-quality metal fabricated products. Today, we would see how automation has brought a significant change in the working and delivery module of metal fabrication.

- Ease of work for workers: Metal manufacturing requires high-skilled laborers, who are diligent and dedicated to work, as it requires precision in work, which leads to lot of strain in the laborers. Most of the high-risk jobs are nowaccomplished with the help of technological advancement, which ultimately reduces fatigue and strain in the workers. Robots are good support in finishing the mundane works as lifting, sorting, carrying of materials, which unnecessarily used to put pressure on the workers.

- Streamlining of data: With integration of apps and software, it has become simple to coordinate between the departments and get an idea on the work. Technology has given easy and fast access to records and work history for comparing project requirements and adding value to new projects. It also aids in identifying mistakes and avoiding them in the future, it improves the quality of work tremendously.

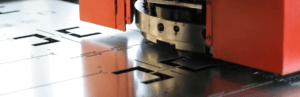

- Improves Efficiency:Robots do not get tired or bored, so it is obvious that the quality of work would be improved and much efficiently accomplished. Many tiring work which otherwise would have required a lot of time and energy, could be done at a faster speed, while human energy could be invested in performing more precision work like fabricating intricate designs, sharing inputs of metal sheets and its types for better work.

- Brings Safety:When majority of high-risk work is done by robots, safety for workers definitely improves. When metal fabricators employ AI-powered working technique, it is programmed to check on risks involved in machines. They improvise the safety features in the machines by alerting the management. Also, when the fatigue or strain is reduced, automatically safety in the working will improve.

- Brings Consistency: Automation brings consistency in the metal fabrication work as with programmed techniques, it is easy to achieve the desired outcome. Especially, those work where high precision is required, automation proves to be very useful. With proper programming, it is convenient to achieve the desired outcome. This is in fact one of the reasons why we are able to see better designs, intricate metal work and amazing architectural wonder from metals like steel, aluminum, iron etc.

Omni Steel Supply is a professional metal manufacturer who provides all kind of metal cutting, welding, molding and designing required for metal fabrication. To know more about their nature of work, get in touch today.