When it comes to precision drilling in metal works and industrial applications, choosing the right drilling tools and solutions is paramount. One such tool gaining prominence is the flat bottom drill bit. This article delves into the everything you need to know about flat bottom drill bits, their advantages, and how they are used in steel drilling and other metal works.

Understanding Flat Bottom Drill Bits

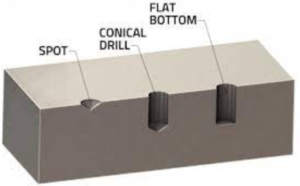

Flat bottom drill bits, as the name suggests, are designed with a flat cutting edge at the tip instead of the traditional pointed tip found in standard twist drills. This unique design offers several advantages that make it an ideal choice for specific applications.

Advantages of Flat Bottom Drill Bits:

- Accurate Hole Bottoms: The primary advantage of flat bottom drill bits is their ability to create precise and flat-bottomed holes. This is especially crucial in scenarios where holes need to be created for fasteners or other components that require a flush fit.

- Reduced Chatter: Chatter, which refers to the vibrations that occur during drilling, can affect the quality of the hole and the overall drilling process. Flat bottom drill bits are designed to reduce chatter, resulting in smoother and more accurate drilling.

- Improved Hole Quality: The flat bottom design minimizes the risk of burrs or irregularities at the hole entrance and exit, contributing to a cleaner and more polished end result.

How Flat Bottom Drill Bits Are Used in Metal Works:

- Precision Machining: Flat bottom drill bits are a preferred choice in precision machining tasks that demand high accuracy and a smooth finish. They are commonly used in applications where holes need to be drilled for dowels, pins, and other components requiring a flush fit.

- Countersinking and Counterboring: Flat bottom drill bits are excellent for creating countersinks and counterbores, which are used to accommodate screws and other fasteners, allowing them to sit flush with the material’s surface.

- Hole Alignment: In applications that require precise alignment of multiple holes, flat bottom drill bits help ensure that the holes are accurately positioned and parallel to each other.

- Stack Drilling: Flat bottom drill bits are useful when drilling through stacked materials, as they prevent the bit from wandering and ensure that all layers are drilled accurately.

- Removing Material: Flat bottom drill bits can be used to remove material from a specific area, creating recesses or pockets in the material for various purposes.

Choosing the Right Flat Bottom Drill Bit:

When selecting a flat bottom drill bit, consider factors such as the material you’re drilling into, the desired hole size, and the required level of precision. Different materials and sizes may require specific types of flat bottom drill bits to achieve optimal results.

In Conclusion:

Flat bottom drilling offers a range of benefits that make it an invaluable technique in the realm of steel drilling and other metal works. The accuracy, reduced chatter, and improved hole quality provided by flat bottom drill bits contribute to enhanced precision and overall efficiency in various applications. When seeking drilling solutions for your metalworking projects, considering the advantages of flat bottom drill bits could be a step toward achieving superior results.

– : !! Contact for Steel Drilling Services

Call us at +1 718-523-5400 or mail us at info@omnisteelsupply.com

#steel #metal #construction #welding #architecture #iron #handmade #metalwork #stainlesssteel #industrial #manufacturing #newyork #nyc #steelindustry #nycconstruction #nycmetalworkers #steeldrilling #drillingtools #drillingsolutions