Aluminum is a versatile and widely used material in various industries, and one of its common forms is the aluminum sheet. Aluminum sheets find applications in construction, manufacturing, aerospace, and more due to their exceptional properties. In this article, we will explore what aluminum sheets are, why they are used, the common types available, and their diverse range of applications.

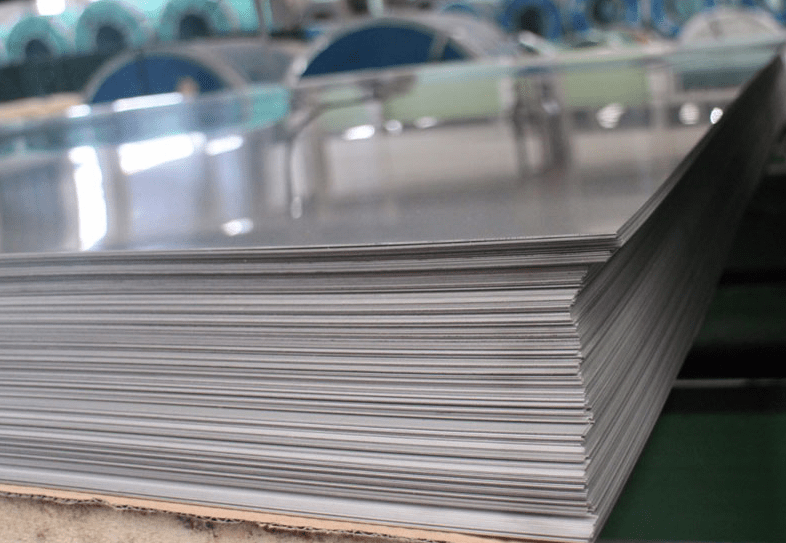

1. What is an Aluminum Sheet?

An aluminum sheet is a flat piece of aluminum that is fabricated in various thicknesses and sizes. It is a result of rolling or pressing aluminum ingots through a series of rollers until the desired thickness is achieved. Aluminum sheets can range from paper-thin foils to thick plates, depending on the intended use. The sheets are known for their lightweight, corrosion resistance, excellent thermal and electrical conductivity, and overall durability. These properties make aluminum sheets an attractive choice in a wide range of applications.

2. Why use an Aluminum Sheet?

Aluminum sheets are favored for several compelling reasons:

– Lightweight: Aluminum is exceptionally lightweight, making it an ideal choice for applications where weight reduction is critical. For example, in aerospace, the lightweight nature of aluminum helps reduce fuel consumption and enhance overall performance.

– Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which prevents corrosion, making it suitable for outdoor and marine applications.

– Excellent Conductor: Aluminum is an excellent conductor of heat and electricity, making it an ideal choice for heat sinks, electrical enclosures, and electrical conductors.

– Versatility: Aluminum sheets can be easily machined, cut, and formed into various shapes, making them adaptable for different applications.

– Recyclability: Aluminum is a highly sustainable material as it can be recycled without losing its essential properties, reducing environmental impact.

– Aesthetic Appeal: Aluminum sheets offer a sleek and modern appearance, making them popular for architectural and design purposes.

3. What are the common types of Aluminum Sheet?

Aluminum sheets are available in various grades and alloys, each with its unique properties. The most common types of aluminum sheets include:

– 1100 Aluminum Sheet: This pure aluminum sheet is soft and highly formable, making it suitable for decorative and non-critical applications.

– 3003 Aluminum Sheet: This alloy combines strength and corrosion resistance, making it ideal for applications like food and chemical handling equipment.

– 5052 Aluminum Sheet: Known for its high fatigue strength, this alloy is often used in marine and automotive applications.

– 6061 Aluminum Sheet: With excellent strength and weldability, it’s a popular choice in structural components, aircraft fittings, and more.

– 7075 Aluminum Sheet: Renowned for its high strength and resistance to stress, this alloy is commonly used in aerospace applications.

4. Common uses of Aluminum Sheet

Aluminum sheets have a wide range of applications across various industries:

– Construction: Aluminum sheets are used for roofing, siding, and structural components due to their corrosion resistance and lightweight nature.

– Aerospace: In the aerospace industry, aluminum sheets are used in aircraft components, from fuselages to wings, thanks to their strength-to-weight ratio.

– Transportation: Aluminum sheets find applications in the automotive industry for body panels, frames, and structural components to reduce vehicle weight and improve fuel efficiency.

– Packaging: Aluminum foils are commonly used for packaging food and beverages due to their barrier properties and flexibility.

– Electrical Industry: Aluminum sheets are used in electrical enclosures, conductors, and heat sinks due to their excellent thermal conductivity.

– Marine: The corrosion-resistant nature of aluminum makes it an excellent choice for boat building and marine equipment.

– Architecture: Aluminum sheets are utilized in architectural applications for building facades, curtain walls, and decorative elements.

In conclusion, aluminum sheets are a versatile material with a broad range of applications, thanks to their unique properties. Whether you are in the construction, automotive, aerospace, or packaging industry, aluminum sheets can offer lightweight, durable, and corrosion-resistant solutions to meet your specific needs. With various types and grades available, choosing the right aluminum sheet for your application is essential to ensure optimal performance and longevity.