Aluminum is a popular material for many applications due to its lightweight and durable properties. However, welding aluminum can be difficult due to its high thermal conductivity and low melting point. In this article, we will explore the different types of welding used for aluminum and their advantages and disadvantages.

Why Is Welding Aluminum Difficult?

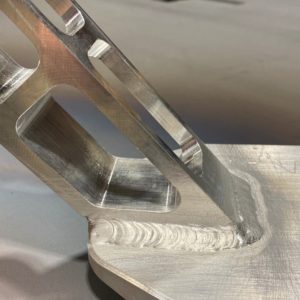

Welding aluminum can be challenging due to several factors. Firstly, aluminum has a high thermal conductivity, which means that it can absorb heat quickly and conduct it away from the welding area. This can lead to problems such as warping, distortion, and cracking during the welding process. Secondly, aluminum has a low melting point, which means that it can be difficult to achieve a stable weld pool without overheating the material. Lastly, aluminum has a tendency to oxidize, which can create a weak joint if not properly cleaned and prepared before welding.

GTAW/TIG Aluminum Welding

Gas Tungsten Arc Welding (GTAW), also known as Tungsten Inert Gas (TIG) welding, is a popular method for welding aluminum. This process uses a tungsten electrode to create an arc, which melts the aluminum and creates a weld pool. The weld pool is protected from oxidation by a shielding gas such as argon. GTAW/TIG welding offers high precision and control, making it suitable for thin and delicate aluminum materials.

GMAW/MIG Aluminum Welding

Gas Metal Arc Welding (GMAW), also known as Metal Inert Gas (MIG) welding, is another popular method for welding aluminum. This process uses a wire feed to deliver a continuous stream of filler metal into the weld pool. The wire is melted by an electric arc, which creates a weld pool that is protected from oxidation by a shielding gas. GMAW/MIG welding is faster than GTAW/TIG welding, making it suitable for thicker and larger aluminum materials.

Laser Beam Welding and Electron Beam Welding- Aluminum Welding

Laser Beam Welding (LBW) and Electron Beam Welding (EBW) are two advanced methods of welding aluminum. LBW uses a high-powered laser beam to melt the aluminum, while EBW uses a beam of high-velocity electrons. Both methods offer high precision and control, making them suitable for complex aluminum structures. However, they are more expensive and require specialized equipment and training.

Resistance Welding – Aluminum Welding

Resistance welding is a method of welding aluminum that uses electrical resistance to create heat. This process involves pressing two aluminum parts together and passing an electric current through them, which generates heat and creates a weld. Resistance welding is a fast and efficient method of welding aluminum, but it is limited to certain types of joints and materials.

In conclusion, welding aluminum requires specialized techniques and equipment due to its unique properties. GTAW/TIG and GMAW/MIG welding are popular methods for welding aluminum due to their versatility and efficiency. Advanced methods such as LBW and EBW offer high precision and control, but require specialized equipment and training. Resistance welding is a fast and efficient method, but is limited to certain types of joints and materials. By choosing the right method for your project, you can ensure a strong and reliable weld for your aluminum structure.

Omni Steel Supply provides end-to-end metal works including metal fabrication and welding services. We deal in all kinds of metal and have a team solely catering to specific needs of our clients. Our welders have extensive knowledge about Tungsten Inert Gas (TIG) and Metal Inert Gas, used for aluminum welding services.

Omni Steel Supply is now introducing top of the line Aluminum Welding services under the supervision of industry experts for your commercial and residential projects backed up with exquisite customer services to ensure your dreams are fulfilled.

Aluminum Welding services New York, Queens, and Jamaica. Reach out to us at +1 (718) 523-5400